Does Sublimation printing, only work on polyester?

Yes, and no,

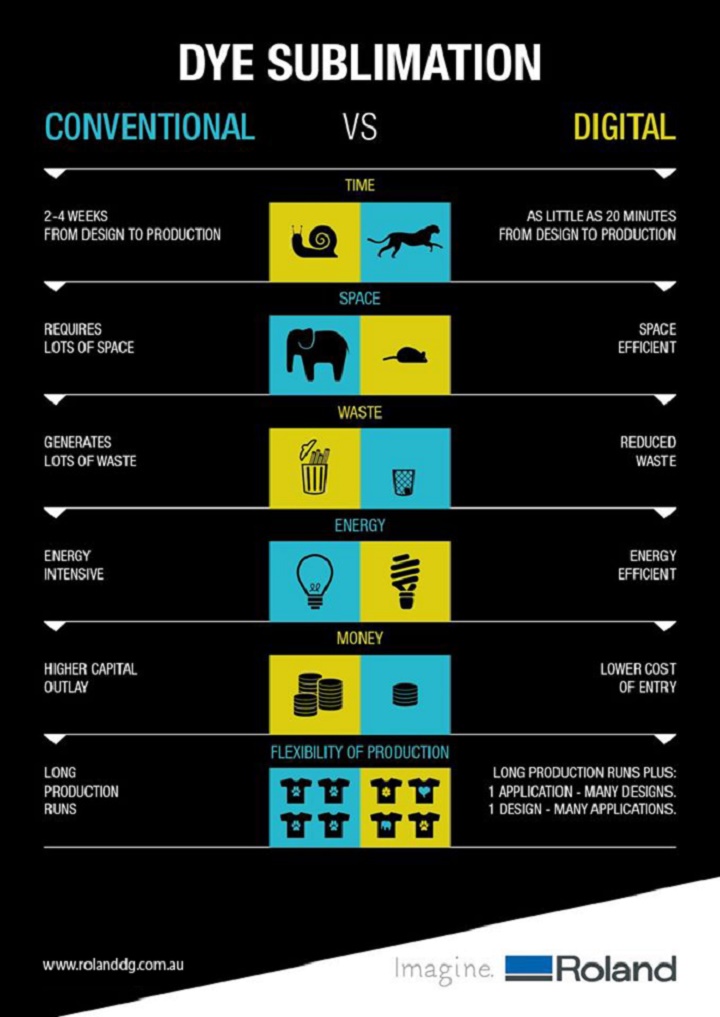

Dye Sublimation printing was specific to100% polyester for garment like, swimwear, activewear and sportswear.

This is obviously the huge downside for uniform industry, therefore, we have developed a suitable cotton backed fabric for dye sublimation, to get sharp and bright colour from cotton backed fabric without the white fluff from the cotton, that was a big challenge.

Normally dyeing of polyester/cotton blended fabric required double bath dyeing of polyester/cotton blend fabric gives far better results in terms uniformity of shades in both light and dark shades, but dye sublimation is single heat transfer dyeing process, , for decades the clothing industry only used 100% polyester fabric for dye sublimation, if you jump onto the internet now, the result for the best fabric for dye sublimation printing will still be polyester.

At Australian Spirit, we always believe that there is always the solution for the problem, after months of research and discussion with our fabric mill and dying house, we have finally developed our first-generation dye-sublimation friendly cotton backed fabric in 2016, up to today, the fabric is already 4th generation.

Our cotton backed fabric also features with UPF 50+, it’s the best choice for school wear, out-door workwear, and corporate uniforms.

- Need a picture of cotton backed fabric in comparison.

- UPF 50+

- ILLUSTRATOR OF COTTON BACKED

Recent Comments